We customize discharge tungsten needle, grinding point tungsten needle and ion tungsten needle for air purifier, air disinfector, electrostatic precipitator and other fields, including tungsten, molybdenum and alloy, stainless steel, titanium alloy and monocrystalline silicon, which are mainly used in air purification and disinfection, machinery manufacturing and welding, electrical appliance manufacturing, electrostatic precipitator, clean new energy, optical fiber fusion, environmental protection and health, semiconductor, medicine and so on Therapeutic equipment and various plasma generator fields. The tungsten and molybdenum raw materials with stable quality are used. Each discharge tungsten needle is densified. The internal structure is uniform and dense, which ensures the high melting point (3410 ℃), high strength and high temperature stability of the product.

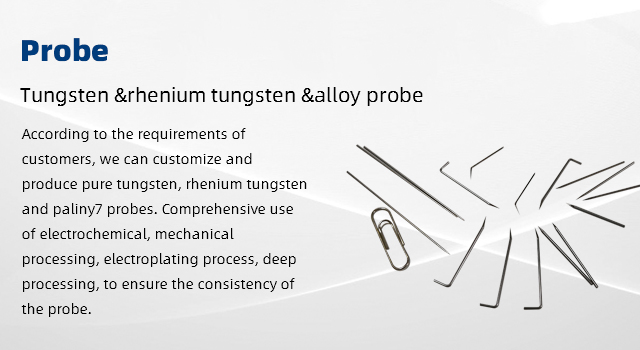

The discharge tungsten needle of hengmi, with the tip min controlled at 0.05um (50nm), can also be customized to any tip in the range of 50nm to 200mm.

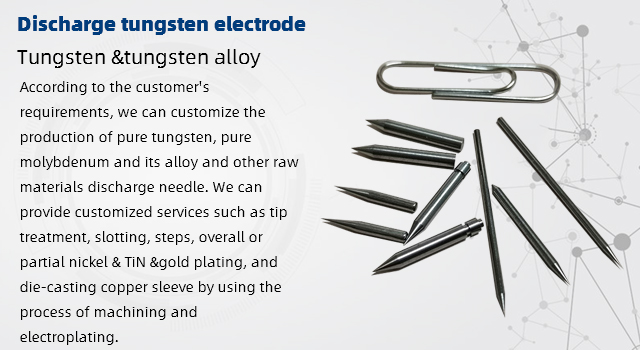

In the aspect of tip processing, bending forming, slotting and other deep processing, the needle tip can be sharp, customized, platform and arc shape.

The needle cone has high precision, high strength and elastic modulus, smooth surface and no damage, and the finish can reach below ra0.25, almost mirror surface.

It can also provide customized services such as overall or partial plating (nickel, tin, gold, etc.), die-casting copper, metal sleeve, etc.

We have been studying in refractory metal industry for many years. We can customize different brands, shapes and precision tungsten needles according to drawings or samples.