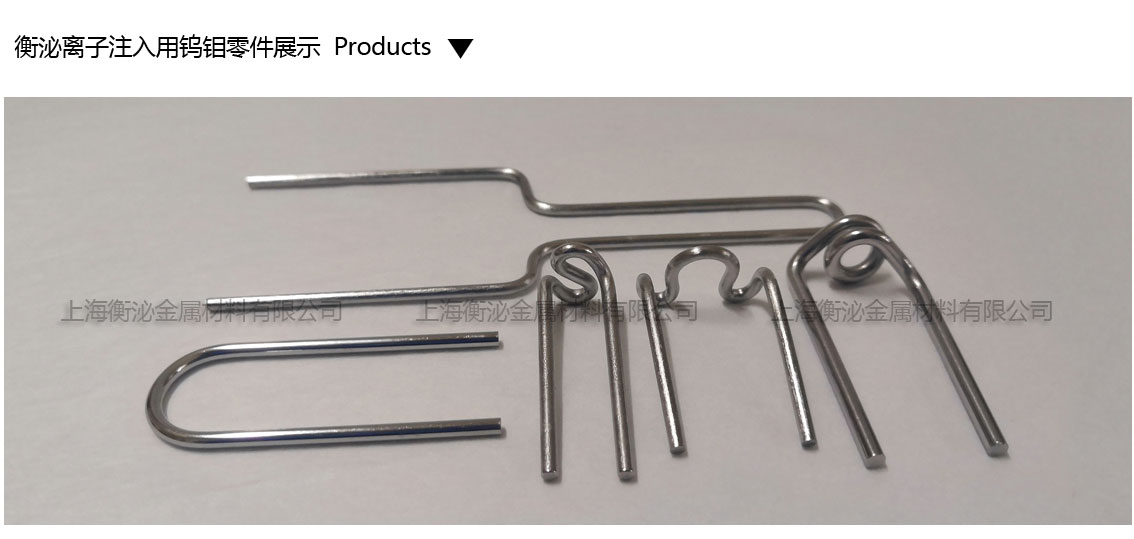

Tungsten&molybdenum parts for ion implantation

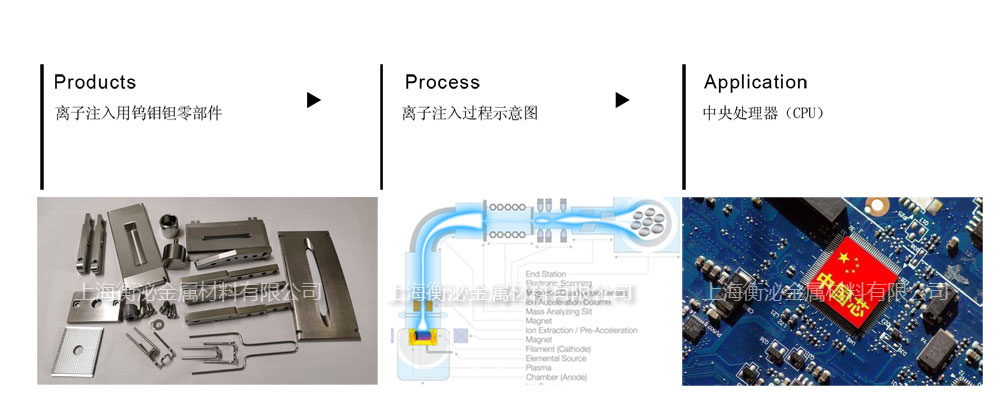

Tungsten&molybdenum parts for ion implantationIon implantation, one of the wafer manufacturing processes, is a key area of semiconductor industry. Ion implantation technology is a kind of high-tech which can change the performance of materials. It is mainly used in semiconductor material doping, metal, ceramics and other fields. It is an indispensable process in the contemporary manufacturing of large-scale integrated circuits. The temperature of semiconductor manufacturing process is as high as 1400 ° C, and the corrosive gas, electromagnetic field and strong mechanical force will cause many problems for traditional materials.

We use high-temperature parts made of tungsten, molybdenum, tantalum and so on to apply in the process of ion implantation, which perfectly integrates the characteristics of corrosion resistance, material strength, high thermal conductivity and absolute purity, with stable performance. It ensures the efficient generation of ions. The optical path leading to the wafer is accurate and free of impurities.

Application diagram of ion implantation components:

Product advantages:

· Filament (tungsten and tungsten alloy)

· Arc gap (tungsten and its alloys)

· Clamps (tungsten, molybdenum and their alloys)

· Cathode (tungsten and its alloys)

· Spare parts (tungsten, molybdenum, tantalum and their alloys)

· Cavity (tungsten, molybdenum and their alloys)

HengMi products:

· Filament (tungsten and its alloys)

· Arc gap (tungsten and its alloys)

· Fixture (tungsten, molybdenum and their alloys)

· Cathode (tungsten and its alloy)

· Spare parts (tungsten, molybdenum, tantalum and their alloys)

· Cavity (tungsten, molybdenum and their alloys)

Solution of ion implanted tungsten molybdenum parts:

With the precision of 0.001mm and more than 10 years of experience in the semiconductor industry, we produce tungsten and molybdenum parts strictly in line with OEM (original equipment manufacturer) standards. With the special formula for tungsten molybdenum plate and bar, combined with complete precision machining and testing equipment, we can customize and process tungsten molybdenum parts with different precision and shapes according to the requirements of customers, and provide key tungsten, molybdenum and tantalum components and consumables for arc reaction chamber of ion implanter (large beam, medium beam and high energy).