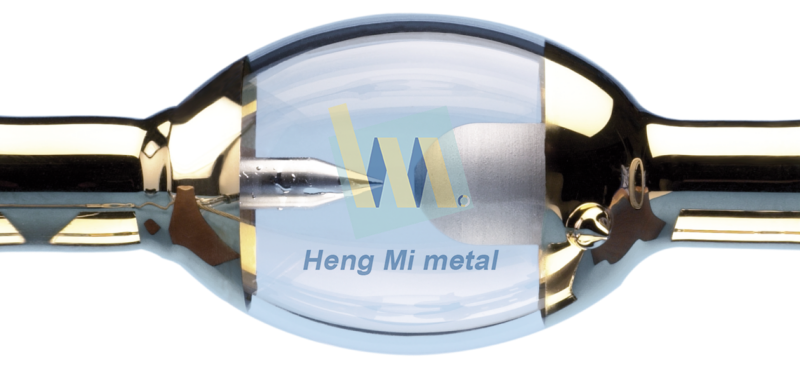

Tungsten electrode for lamp

Tungsten electrode for lampHengmi provides key tungsten and molybdenum materials for electric light source and electric vacuum, including pure tungsten (> 99.99%), tungsten aluminum (> 99.95%), potassium doped tungsten (> 99.95%), cerium tungsten, thorium tungsten, pure molybdenum, molybdenum lanthanum and other wires and bars, as well as customized tungsten and molybdenum electrode parts with various shape accuracy.

Hengmi uses the tungsten molybdenum raw material with stable quality. Different from the ordinary products, our products have relatively high density and uniform internal structure after deep densification treatment. The resistance to electron bombardment and corrosion of the electrode is greatly improved, and the service life is obviously better than that of the electrode without deep densification treatment. Its thermal conductivity, creep resistance, durability, optical output, emission electron, electronic spillover work, thermal conductivity, reliability and mechanical stability can meet the customer's customized requirements.

Hengmi product:

· Cathode: cerium tungsten (WC-20, wc-40), thorium tungsten (wt-10, wt-20), pure tungsten (w99.95% - 99.99%), potassium doped tungsten.

· Anode: cerium tungsten (WC-20, wc-40), pure tungsten (w99.95% - 99.99%), potassium doped tungsten

Specification parameter table:

Tungsten molybdenum electrode precision machining service:

With the help of the company's advantages in processing, hengmi can control the processing accuracy of 0.001mm, and can process various brand electric light sources or vacuum tungsten molybdenum parts according to the drawings or samples. The electrode of hengmi precision machining is applied to the field of electric light source and electric vacuum, including the field of special light source such as ultra-high pressure mercury lamp, ultra-high pressure xenon lamp, flash lamp, laser xenon lamp, digital film projection lamp, searchlight, etc. Customized and standard electrodes can be produced and processed. In order to serve you more effectively, please prepare the following information before contacting us:

1. Sealing process

2. Barometric parameters

3. Arc length data

4. Product drawing

5. For problems encountered at present, send the drawings to:sales@sh-tungsten.com or call 021-59241040 for consultation