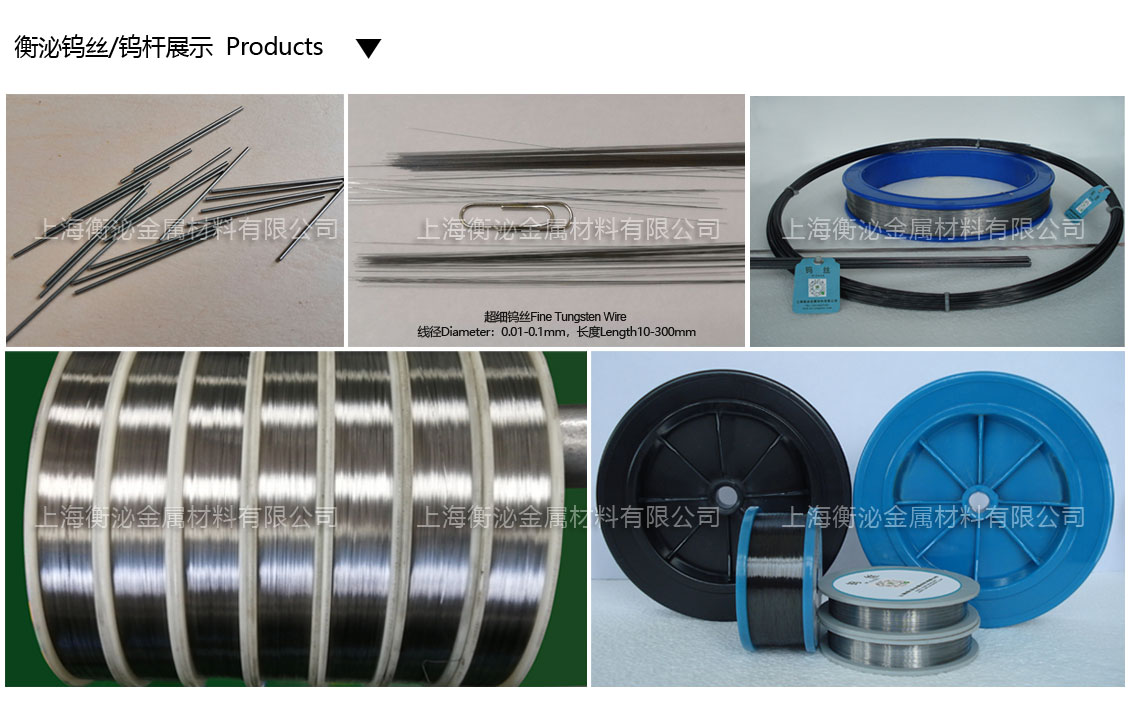

Tungsten wire&tungsten rod

Tungsten wire&tungsten rodAmong all metals, tungsten has the highest melting point, low vapor pressure, low thermal expansion, good thermal conductivity and low electron spillover work.

Hengmi produces tungsten wires and rods for the field of electric light source and vacuum. It uses tungsten raw materials with stable quality. Its thermal conductivity, creep resistance, durability, optical output, emission electronics, reliability and mechanical stability can meet the customized requirements of customers. It is mainly used in the manufacturing of electric light source, electric vacuum device, various heating components, environmental protection, medical equipment, semiconductor and other fields.

High temperature performance:According to different purposes of customers, subdivide various high temperature performance requirements.

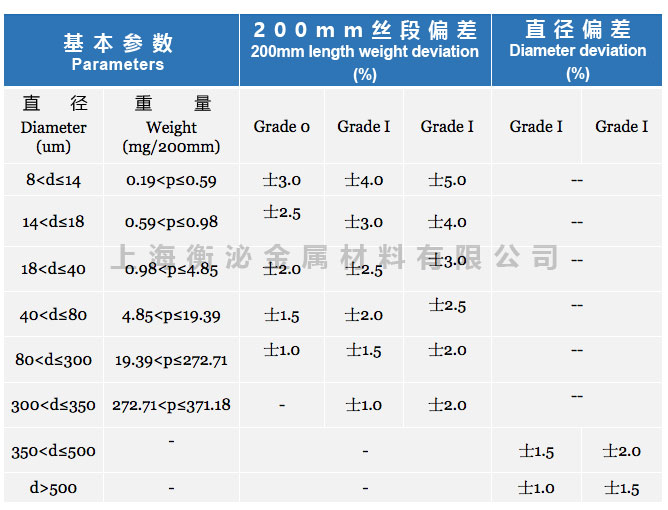

Line diameter consistency:The quality difference of any two continuous sections of 200 mm tungsten wire shall not exceed 0.5% of the nominal specification.

Straightness:Straightening tungsten wire:For tungsten wire with diameter less than 100 μ m, the natural sag height of every 500mm wire section shall be ≥ 450mm; for tungsten wire with diameter more than 100 μ m, the arc height of every 100mm chord length shall be ≤ 10 mm. Surface condition: the surface is smooth, free of defects such as cracks, burrs, scratches, pits, unevenness, oil stain, etc.

Winding performance:In the process of wire winding, tungsten wire does not crack continuously.

Specifications and tolerances:

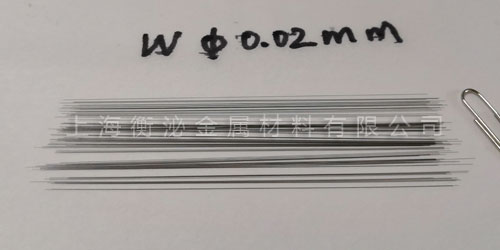

Note: the specification tolerance can be customized according to the customer's requirements, or the surface polishing and grinding state and fixed length ultra-fine tungsten wire can be provided according to the customer's requirements (such as: diameter 0.02-0.1mm, length 5-200mm).