TIG Welding tungsten electrode

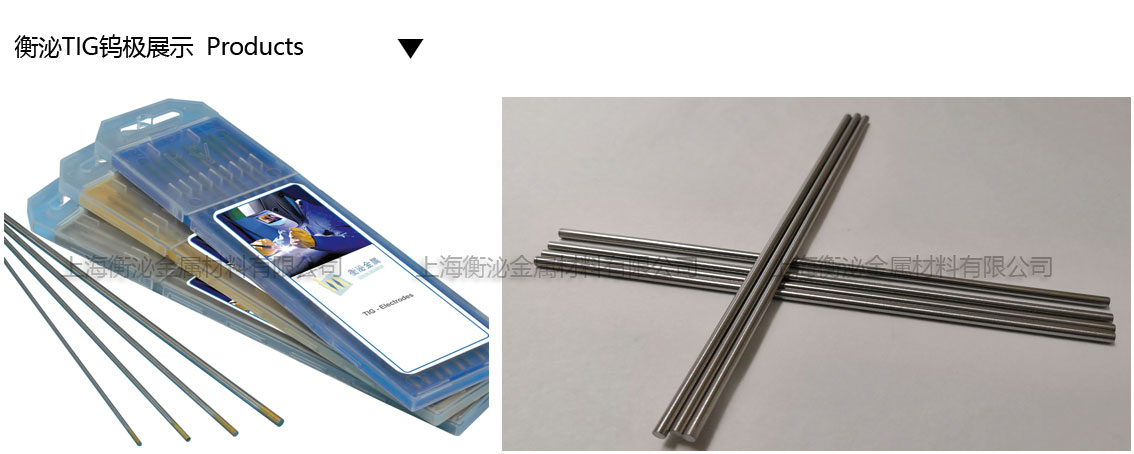

TIG Welding tungsten electrodeTIG welding tungsten electrode, also known as tungsten needle, tungsten rod and tungsten electrode, is made of pure tungsten or doped tungsten rod by processing such as spinning section, stretching, straightening, cutting, polishing and coloring.

Hengmi uses tungsten raw materials with stable quality, which can meet the requirements of customers in arcing, durability, emission electronics, reliability and mechanical stability. TIG welding tungsten electrode produced by hengmi metal integrates excellent arc striking and striking performance, large current carrying capacity and excellent burn resistance. It can be used in DC and AC processes.

Type | Electric current | Application | Technology | Advantage |

Multiple tungsten complex(violet) | AC/DC | Non alloy and low alloy steel, stainless steel, aluminum alloy, magnesium alloy, titanium alloy, nickel alloy, copper alloy, thermal spraying, special light source anode and cathode, etc | Automatic welding, robot welding, aluminum welding, cold welding and other welding fields. | Easy arcing |

WL15(golden) | DC | Non alloy and low alloy steels | Manual welding, automatic welding | Easy arcing |

WL20(blue) | DC小大电流 | Non alloy and low alloy steels | Manual welding, automatic welding | Easy arcing |

WC20(gray ) | DC | Non alloy and low alloy steels | Manual welding, | Easy arcing |

WT20(red ) | DC | Non alloy and low alloy steels | Manual welding, automatic welding | Easy arcing |

WP(green) | AC | Aluminum alloy, copper alloy, thermal spraying, special light source anode, etc | Manual welding, automatic welding | Excellent arc stability |

Tungsten electrode precision machining service:

The machining accuracy of hengmi is controlled at 0.001mm, and various brands of tungsten electrodes can be processed according to drawings or samples. The electrode parts processed by hengmi metal are widely used in mechanical manufacturing and welding, electrical manufacturing, automotive electronics, semiconductor electronics, electronic equipment and other industries.