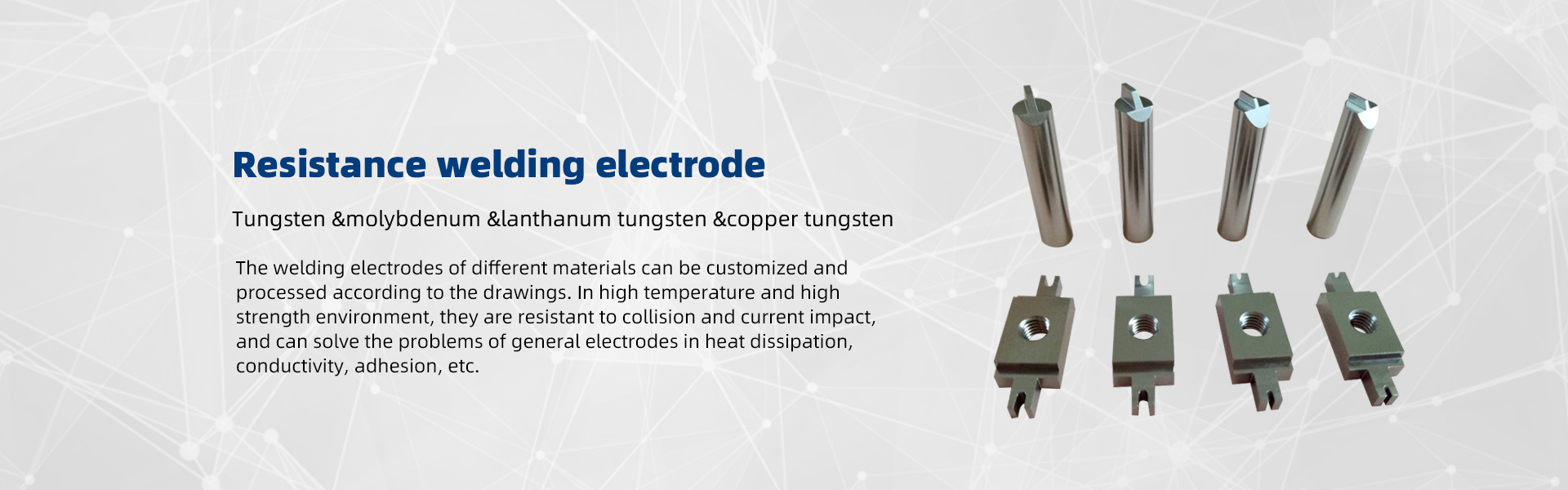

Tungsten & molybdenum electrodes for resistance welding

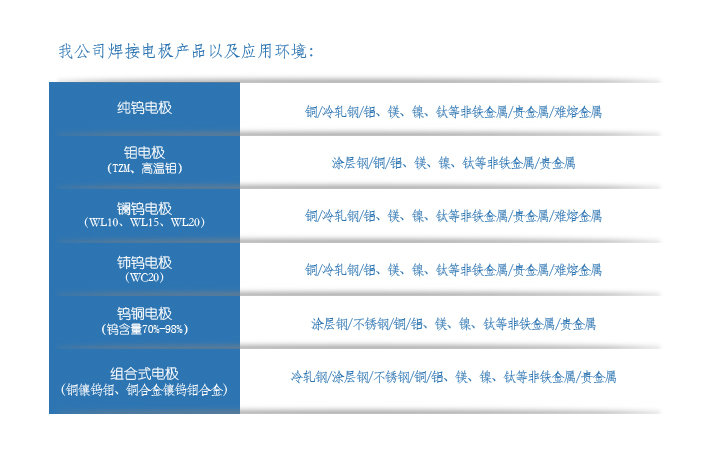

Tungsten & molybdenum electrodes for resistance weldingOur resistance spot welding electrode materials are composed of tungsten, molybdenum and their alloys, and combined with copper. Compared with the traditional tungsten molybdenum electrode on the market, our electrode has excellent high temperature stability and longer service life.

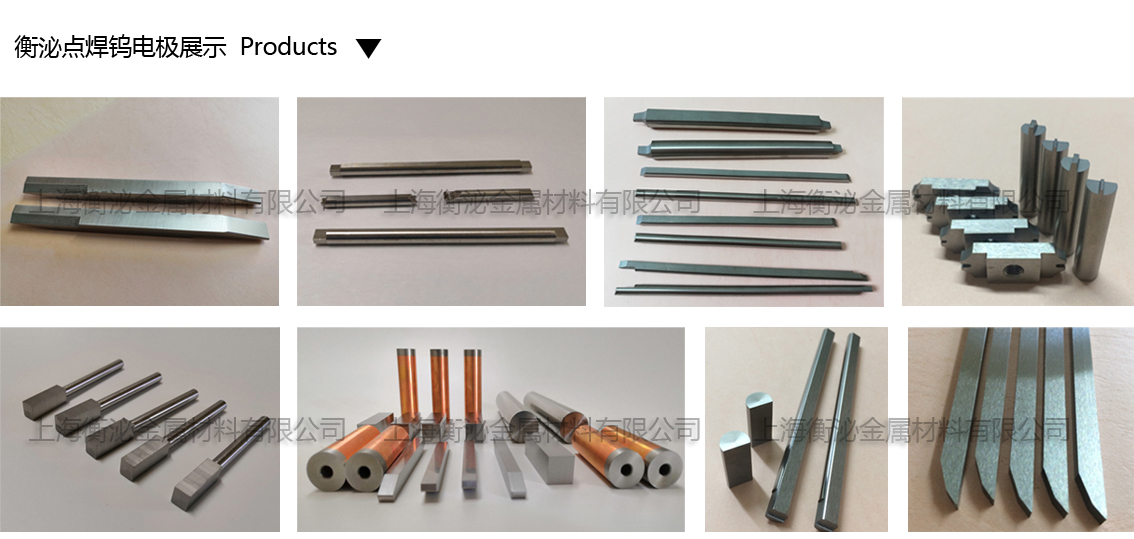

Hengmi's product engineer has established the production process for resistance spot welding industry through years of exploration. From the formula of special materials for spot welding to the finished electrode with stable machining quality, we can not only provide standard bar tungsten molybdenum electrode, but also customize and process according to customers' welding process, welding requirements and product drawings. It can effectively help customers extend the service life of electrode, improve the welding quality, ensure the smooth operation of automatic production line, and reduce the shutdown rate.

Our resistance spot welding tungsten molybdenum electrode has the characteristics of stable conductivity and high temperature stability, collision resistance, non stick workpiece, etc., so as to reduce electrode consumption.

Advantages of W&Mo electrodes in Hengmi spot welding:

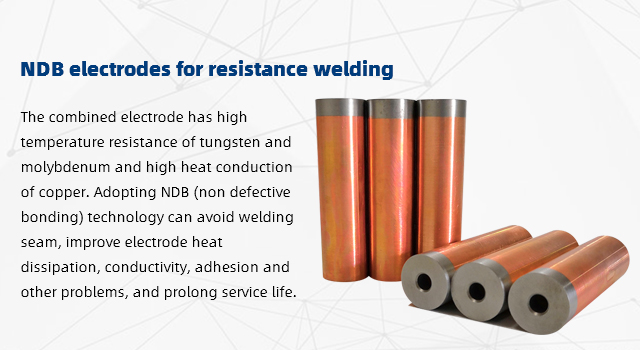

1.Each of our electrodes has been densified, with relatively high density and uniform internal structure, which can maintain constant resistance and stable conductivity.

2.The inlaid electrode adopts NDB (non defective bonding) technology, without pores, and the connection strength is more than 130 MPa; it realizes the integration of copper, tungsten and molybdenum refractory metals, and the combination degree is close to 100%.

3.Using the special formula materials for resistance welding, the raw materials with stable quality, giving full play to the physical characteristics of high melting point of tungsten, adding rare earth elements, further optimizing the high temperature stability, creep resistance, high hardness, impact resistance, not easy to deform, no false welding, and solid solder joints;

4.Combined with many years of experience in the production and processing of resistance welding electrodes, the site of resistance welding can be understood, and the improved design scheme can be provided based on the actual situation of customers.