NDB electrode&Back cast electrode

NDB electrode&Back cast electrodeInlaid electrode is one of the resistance welding electrodes, which has stable conductivity, heat dissipation and other properties in some specific welding environments. Therefore, compared with the traditional electrodes (such as tungsten, molybdenum, copper and their alloy electrodes), the application effect is better.

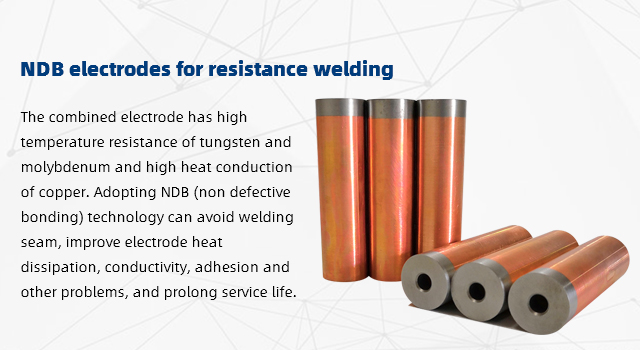

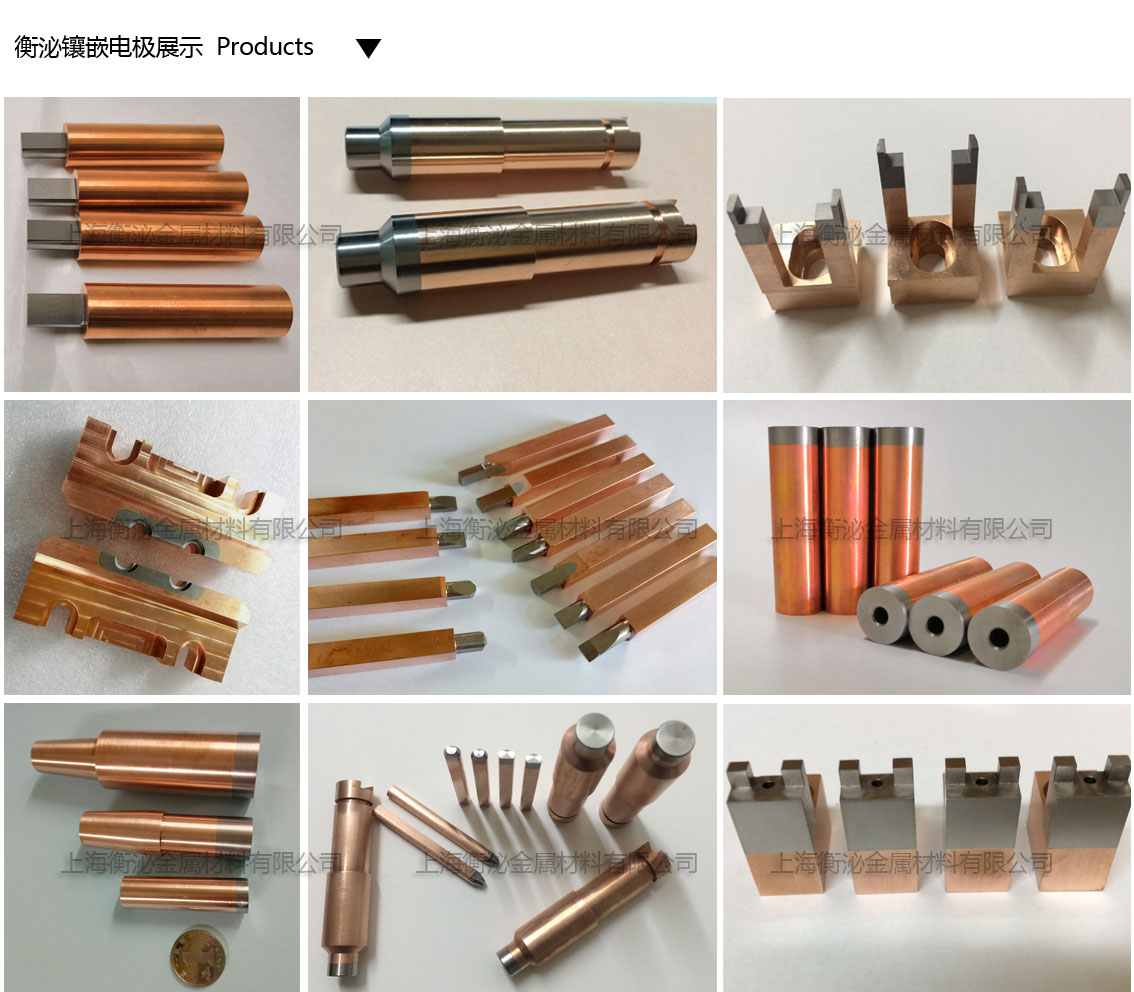

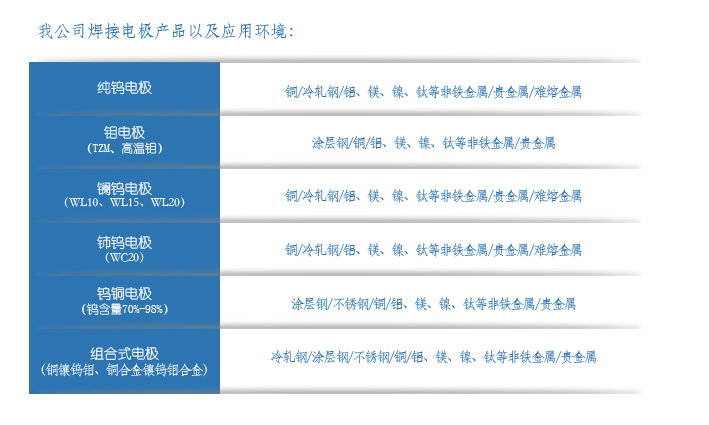

Our production of resistance welding inlaid electrode (also called:Back cast electrode &NDB electrode&copper inlaid tungsten electrode&copper inlaid molybdenum electrode&copper inlaid tungsten alloy electrode&copper inlaid molybdenum alloy electrode&copper inlaid tungsten copper electrode, etc.) adopt pure tungsten, pure molybdenum and its alloy as the welding end, and the rod adopts chromium zirconium copper and oxygen-free copper. Different from ordinary electrodes, our inlaid electrodes are connected by NDB (non defective bonding) in a vacuum environment, also known as NDB welding electrode, which has stable conductivity and heat dissipation. The end of the electrode can be cooled continuously, reducing the heat load of the end electrode head, thus increasing the service life of the electrode and reducing the production cost.

Internal display of cut Back cast electrode &NDB electrode:

Advantages of Hengmi NDB electrode:

1. Copper are integrated with tungsten&molybdenum refractory metals. NDB integrated connection process is adopted. No solder is added. There is no hole in the inner part. The connection strength is more than 130 MPa. It has excellent conductivity and thermal conductivity, so as to ensure that the electrode end can be continuously cooled, thus increasing service life and reducing electrode consumption.

2. The end of each electrode is densified and has high density and uniform internal structure.

3. Using the special formula materials for resistance welding, the raw materials with stable quality, giving full play to the physical characteristics of high melting point of tungsten, adding rare earth elements, further optimizing the high temperature stability, creep resistance, high hardness, impact resistance, not easy to deform, no false welding, and solid solder joints.

4. Combined with many years of experience in the production and processing of resistance welding electrodes, the site of resistance welding can be understood, and the improved design scheme can be provided in combination with the actual situation of customers.

Precision machining service of inlaid electrode:

According to the customer's drawings or samples, we can process all kinds of precision inlay electrodes. We have many years of experience in precision machining of refractory metals. We can customize many kinds of dissimilar metal connection processes according to customer costs, such as brazing, NDB seamless connection, etc. our processed inlaid electrodes are used in mechanical manufacturing and welding technology, such as the connection of automobile harness, motor, switch contact, ignition coil, brake electronic system, electromagnetic coil, sensor lead and welding copper In the field of spot welding, such as copper strip, copper braided wire joint, etc., it has been widely praised by customers. Customized and standard electrodes can be produced and processed. In order to serve you in time, please contact us to prepare the following information:

1. Materials of parts to be welded

2. Welding data (pressure, current, temperature and other parameters)

3. Specific specification or drawing and sample of electrode

4. Water cooling design status

The current problems are sent to shxhsales@sh-tungsten.com/021-59241040