With the rapid development of science and technology, smart home, artificial intelligence, automatic driving, 5g, battery energy storage and other high technologies have entered the lives of ordinary people, which benefits from the continuous innovation and development of integrated circuit industry. Integrated circuit, also known as IC, refers to the production of specific functional circuits on the wafer through a special semiconductor process flow. It follows Moore's law and goes on from generation to generation. Nowadays, there are hundreds of millions of transistors on an integrated chip the size of a fingernail. So how to produce such a huge and sophisticated chip?

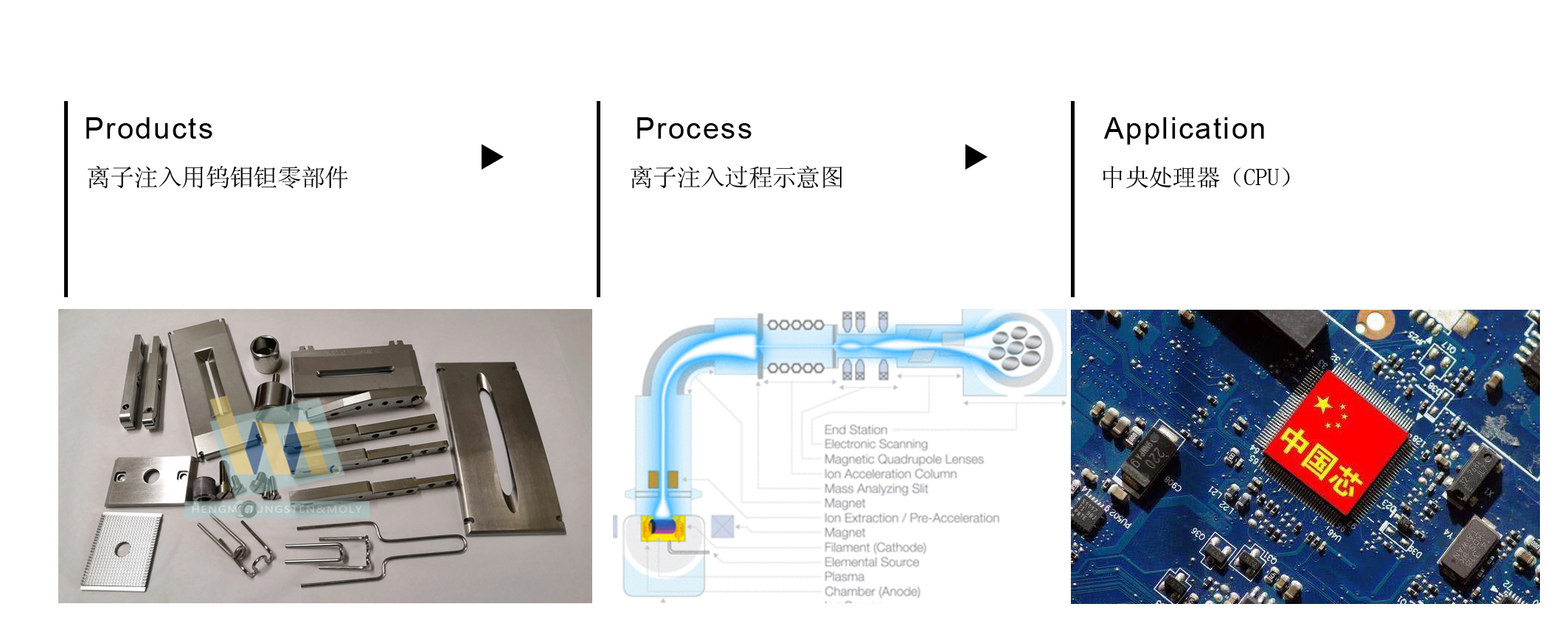

The fabrication of chip mainly depends on micro machining, automation and chemical synthesis technology. The whole process includes: chip design, wafer manufacturing, testing, packaging and so on, among which wafer manufacturing is the most complex process so far. The process of wafer manufacturing includes ion implantation, wafer testing and chip testing, which are inseparable from the refractory metal materials such as tungsten and molybdenum.

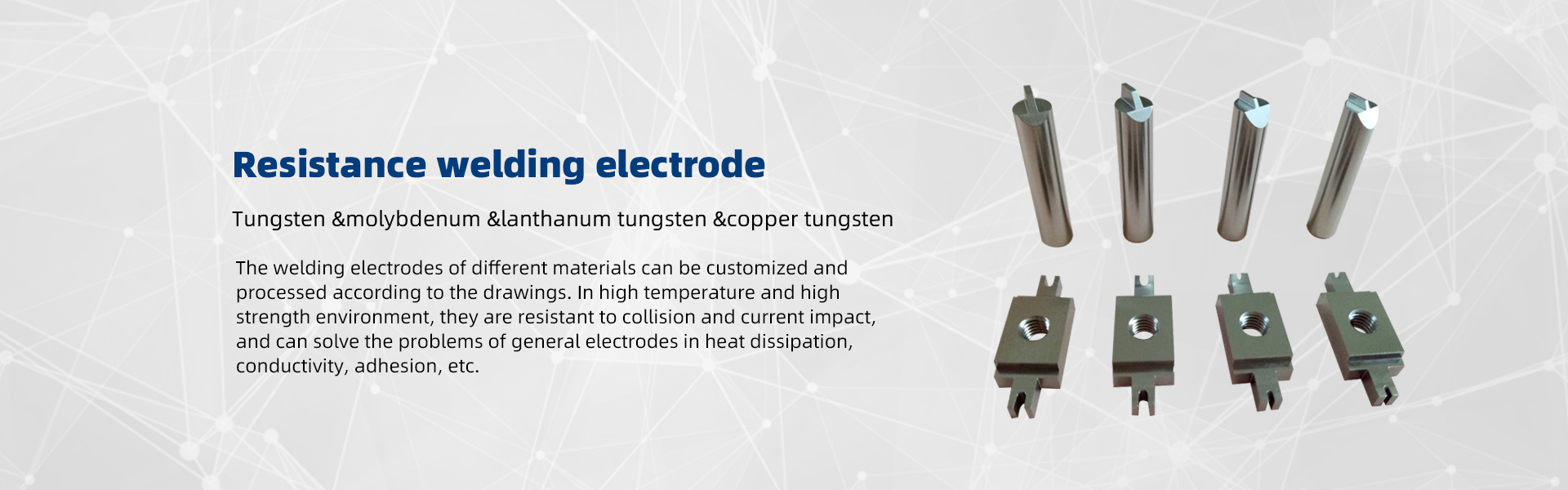

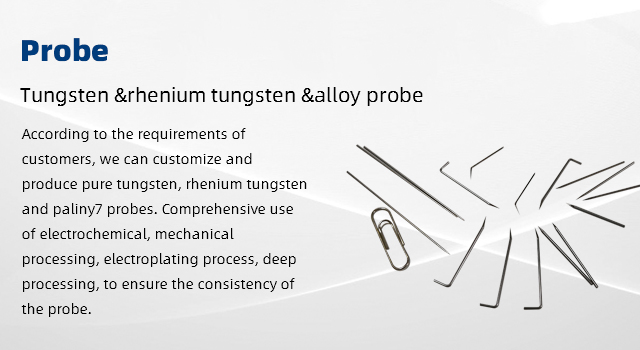

Hengmi metal provides refractory metal products for semiconductor field, including pure tungsten probe, tungsten rhenium probe, key parts of tungsten molybdenum tantalum for ion implantation and customized tungsten molybdenum parts. Our Tungsten Molybdenum parts have been applied to IC and wafer manufacturing in batch.